Basic Info.

Model NO.

Industrial High Shear Circulating Acrylic Emulsion

Certification

CE, ISO

Application Area

Chemical

Layout Type

Verticle

Mixing Drum Shape

Conical

Additional Capabilities

Milling, Granulating, Coating

Operating type

Continuous Operating

Condition

New

Name

Homogenizer Vacuum Mixer

Word

Vacuum Emulsifying Machine

Item

Homogenizer

Mixing Type

Scraper, Homogenizer, High Speed

Material

Stainless Steel

Function

Mixing, Heating, Cooling

Product

for Making Body Cream, Lotion, Cosmeitcs

Product 2

Shampoo, Liquid Soap Mixer

Product 3

High Speed Homogenizer, Mixing, Blending

Brand Used

Siemens, Ormon, Shcneider

for

Daliy Cosmeitcs

Mixing

0-65rpm Top Mixing with Scraper

Mixing 2

Homogenzier 0-3000rpm

Heating Type

Steam Heating and Electric Heating

Touch Material Part

SUS316L or SUS304

Transport Package

Wooden Case

Specification

set

Trademark

Shuangyu

Origin

China

HS Code

8479820090

Production Capacity

1000 Per Year

Product Description

Factory Price Stainless Steel Food Grade Emulsion Pump Mixing Emulsifying High Shear Mixer Inline Homogenizer Pump

SUS304 stainless steel sanitary inline emulsifier mixer

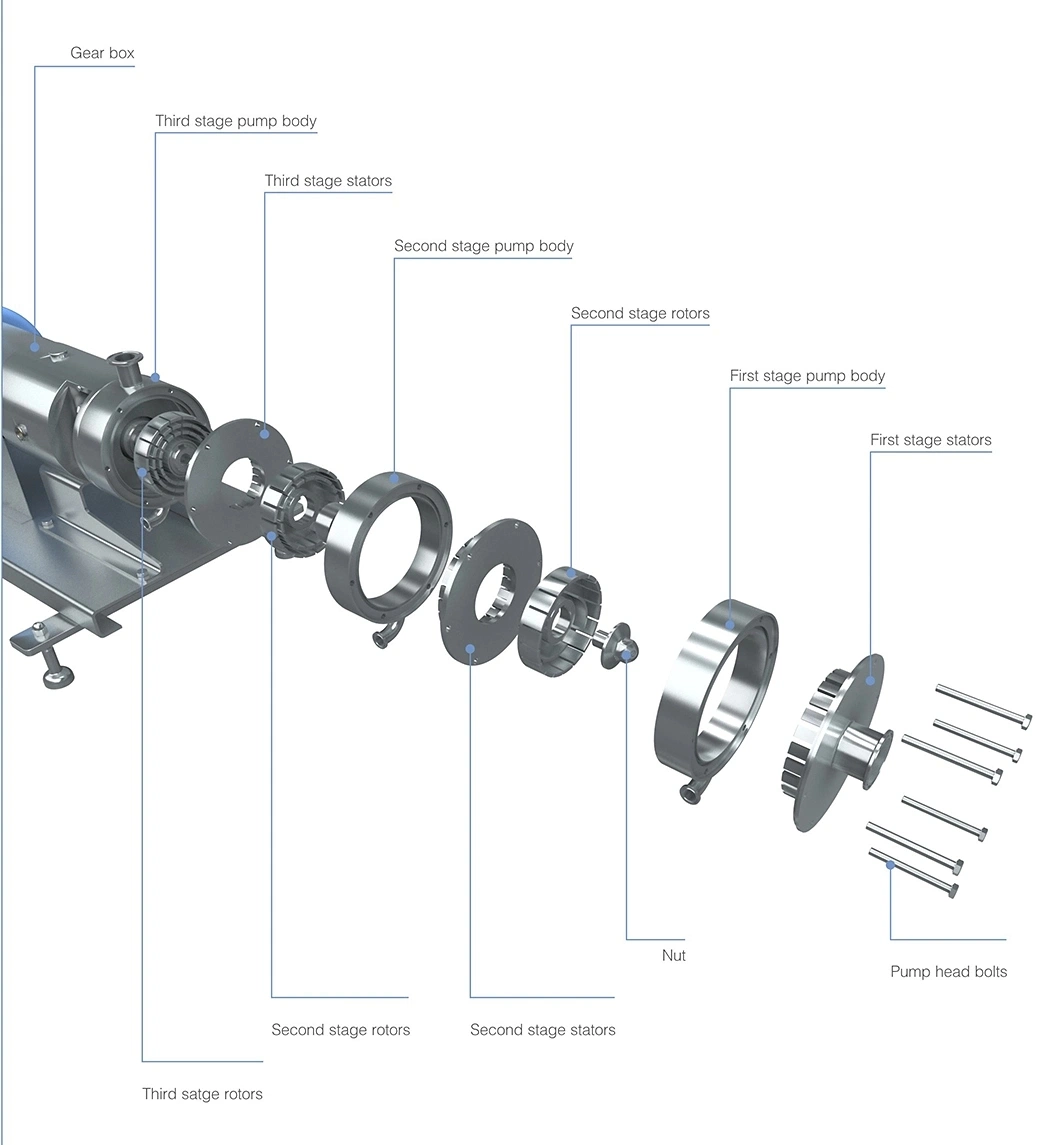

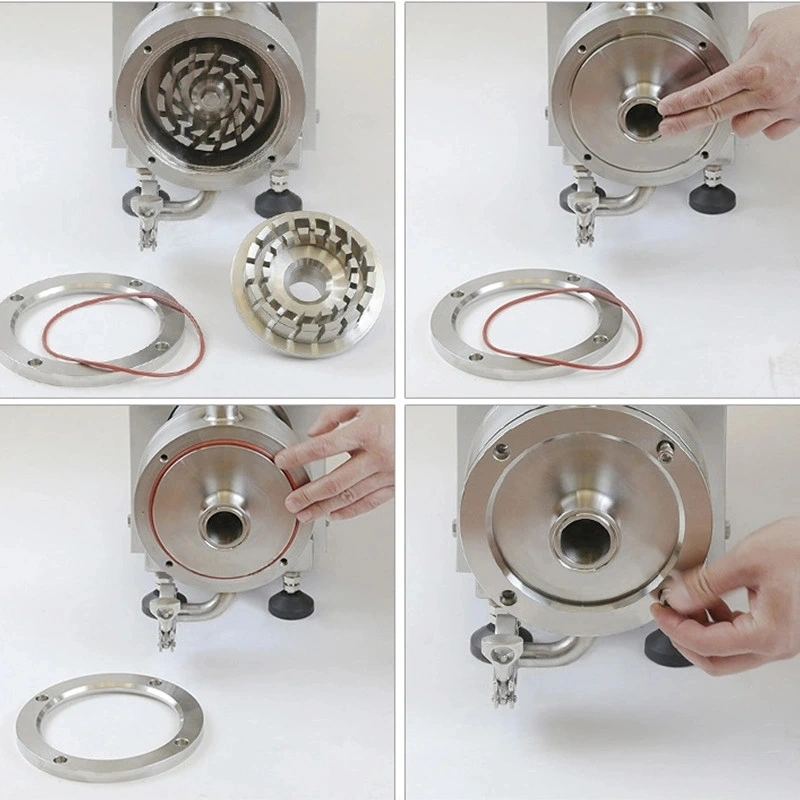

1.SUS304 stainless steel sanitary inline emulsifier mixer can process large quantity of material with various viscosity, very suitable for industry online production.

2.It has the character of better emulsification and better efficiency.In complete range of articles,to meet the different processing option.

3.There are different kind of stainless steel lik 304,316L for different PH requirement.

4.Adopting double mechanical seal,also can match up the water protector.

5.SUS304 stainless steel sanitary Homogenizer pump emulsifying pump has many kind of connection like rigid connection,flexible connection,etc.

1.SUS304 stainless steel sanitary inline emulsifier mixer can process large quantity of material with various viscosity, very suitable for industry online production.

2.It has the character of better emulsification and better efficiency.In complete range of articles,to meet the different processing option.

3.There are different kind of stainless steel lik 304,316L for different PH requirement.

4.Adopting double mechanical seal,also can match up the water protector.

5.SUS304 stainless steel sanitary Homogenizer pump emulsifying pump has many kind of connection like rigid connection,flexible connection,etc.

| Profile type | Best price high performance mixing pumps cosmetics | ||

| material | SS304 or SS316L | ||

| Capacity | 0-130T (Customized) | ||

| pressure | 0-2Bar | ||

| Viscosity | 1-1000000pas | ||

| rotors teeth | Fine/Middle/rough | ||

| temperature | 0-100 celsius degree | ||

| installation | Movebale or Fixed | ||

| connection | Clamp union flange | ||

| motor type | Normal | Ex-proof | inverter |

| Speed | 0-3400RPM | ||

| Technical Parameters | ||||

| Model | capacity (T/H) | Speed(RPM) | out Pressure(bar) | power(KW) |

| RAY-1-80 | 0-1.5 | 2900/3400 | ≤2Bar | 1.5 |

| RAY-1-100 | 0-3 | 2900/3400 | 2.2 | |

| RAY-1-130 | 0-4 | 2900/3400 | 4.0 | |

| RAY-1-140 | 0-5 | 2900/3400 | 5.5 | |

| RAY-1-165 | 0-8 |

2900/3400 | 7.5 | |

| RAY-1-180 | 0-12 | 2900/3400 | 11 | |

| RAY-1-185 | 0-18 | 2900/3400 | 15 | |

| RAY-1-200 | 0-25 | 2900/3400 | 22 | |

| RAY-1-210 | 0-35 | 2900/3400 | 30 | |

| RAY-1-230 | 0-50 | 1450/1700 | 45 | |

| RAY-1-245 | 0-75 | 1450/1700 | 55 | |

| We can customize the equipment according to customer requirements. | ||||

After-sales Service

After-sales Service 1.Warranty time: one year, from the date which the product is qualified commissioning.

Any damage except the wrong operation during warranty period is repaired freely.But the travel and hotel expenses should be count on buyer.

2. Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there until get your agreement.

3. Training services: our engineers will train your staff to operate it during the period of installation and commissioning,

and they will not leave there until your staff can operate it properly and normally.

4. Maintenance services: any malfunction happened, once you inquiry us, we will reply you within 48 hours except the special reasons.

5. Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

6. Certificate services: we can provide related certificates to customers freely according to the request of customers.

7. Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.

8. The file: the Manual Specification, report of the material which used to the equipment and other documents related to the GMP authentication information will be provided by us.

RFQ

Q: Are you a factory?

A: Yes we are a factory with more than 20 years manufacturing experience. One is in Jiangsu,

Another is in Guangzhou next to our office.

Q:I'm new in our industry,but I'm planing to set up a factory, what can I do?

A: We will design the most suitable proposal based on your actual situation, such as the daily production,raw material formula, factory layout, etc. Also we would like to intro- duce some excellent suppliers of raw materials, bottles,labels, etc if needed. After sales, engineer will be send to fields installation, training and commissioning.

Q:Are your machines difficult to operate? How do you teach us using the machine?

A: Our machines are fool-style operation design,very easy to operate.Besides,before delivery we will shoot instruction video to introduce machines'functions and to teach you how to use them.