Basic Info.

Product Description

Product Features

Pneumatic Diaphragm Pump Advantages:

- Idling ,Self-priming , Submerse capability.

- Provide stall-free, ice-free zero leak operation.

- Epoxy-coated air section for tough environmental conditions.

- Low shear force , not easy to damage the material structure.

- Bolt joint design provides even sealing pressure for optimal performance

- Modular air valve,low pulsation operation,providing smooth and rapid changeover.

- No electricity . It's safe and realiable while using in the flammable and explor place .

- Diversity of material,no rotating parts,applicable to various erosive situations.

- Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

- Delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment.

-

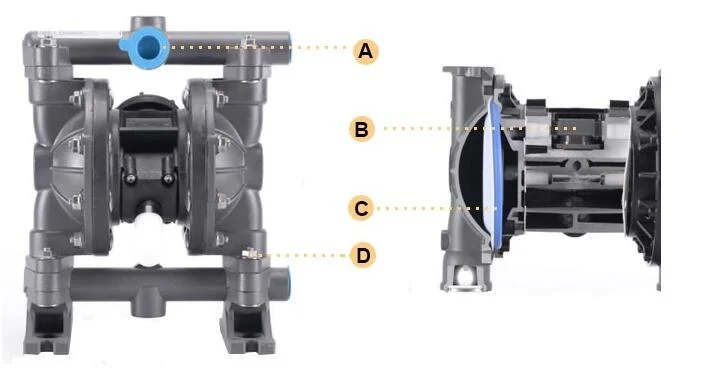

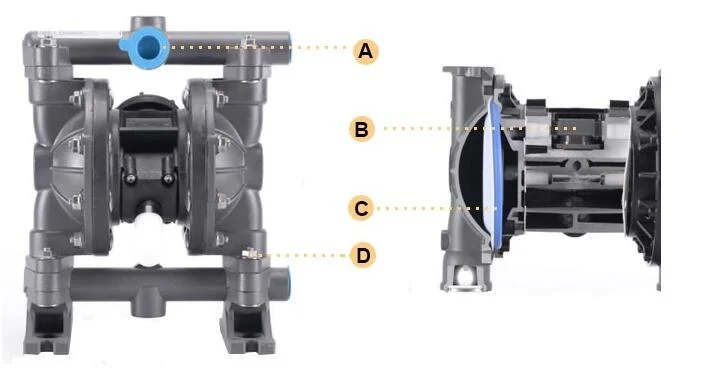

A: Increased munber of ports for installation flexibilityB:Modular air valve for stall-free ,low pulsation operation ,providing smooth and rapid changeover

C:Up to 5x longer diaphragm life for less maintenance and downtime

D:Four bolt joint design provides even sealing pressure for optimal performance

Technical parameters

| Mode | Max.Suction Lift (dry\wet,m) | Max. particle diameter (mm) | Suction and discharge size (inch) | Air inlet size (inch) | Max. flow rate (L/min) | Max. air consumption (m3/min) |

| HY-15/20 | 4 \ 7.6 | 2.5 | 1/2 3/4 | 1/4 | 57 | 0.672 |

| HY-25 | 4 \ 8 | 4 | 1 | 1/2 | 157 | 1.7 |

| HY-40 | 5 \ 8 | 5 | 1½ | 1/2 | 358 | 3.5 |

| HY-50 | 5 \ 8 | 6 | 2 | 1/2 | 587 | 4.9 |

| HY-80 | 5 \ 8 | 9.4 | 3 | 3/4 | 1060 | 9.1 |

Model sheet

Application

Pumping chemicals can be safely done with HY diaphragm pumps. The leak-free design and excellent

corrosion resistance of the pumps ensures a smooth and save pumping all kind of chemicals.

HY AODD Pumps can deal with all kinds of corrosive, volatile, flammable, poisonous fluids with particles

and high viscosity.

2. The pump can suck the paint, pigment, glue and adhesive etc.

3. The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4. The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

5. The pump can suck various toxin and flammable or volatility liquid etc.

6. The pump can suck various wedge water, cement slurry and mortar etc.

7. The pump can suck various strong acid, alkali and corrosive liquid etc.

8. It can be used as a front-step tranmission device of the solid and liquid separation equipment.

Our products have been widely used in daqing oilfield, shengli oilfield, a large number of

cutting-edge key projects such as baosteel,Our products are worthy of your trust

HY Company information

Shanghai Haoyang Pump Valve Manufacturing Co., Ltd.designed and manufactured for over

10 years in Shanghai,China. HaoYang Air-Operated Double Diaphragm (AODD) pumps have earned

industry recognition for premium quality and innovative design. And we supply accessories and

componentssuitable for most AODD pump installations.To ensure suitability for a variety of media,

wetted partsare available in numerous optional materials.

Focus on customer satisfaction is supported with quality and reliability, validated by CE certifications.

We specify only the most durable materials that are dependable and long-lasting. When we combine

the highest-quality products with topnotch customer care, we get outstanding value

FAQ

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: What're your payments ?

A: T/T,Western Union,L/C etc.

3. Q: What about the package ?

A: Standard export plywood case or carton.

4. Q: How long is the warranty ?

A: According to international standards, products in standard operation is 1 year,except wearable parts.

5. Q: The use of products have?

A: The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.

The pump can suck the paint, pigment, glue and adhesive etc.

The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

The pump can suck various toxin and flammable or volatility liquid etc.

The pump can suck various strong acid, alkali and corrosive liquid etc.

6. Q: How product quality and service?

A: Our pump have CE certificate, quality assured, can accept OEM, provide various personalized needs.

If you want to know more details, Please send inquiry to me,

We are very glad to hear from you !

Click " Contact " Now!