- Overview

- Product Description

- Product feature

- Product Parameters

- PRODUCT APPLICATION SCENARIOS

- Detailed Photos

- Customer review

- Company presentation

- Workshop display

Basic Info.

Product Description

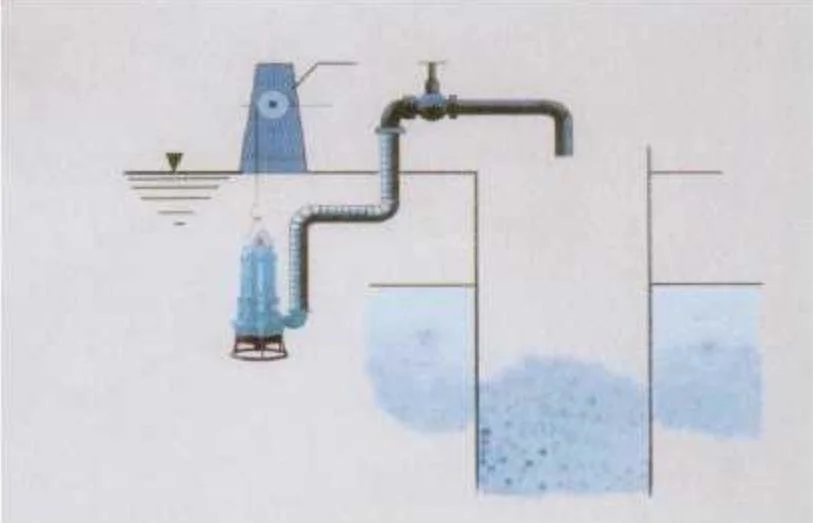

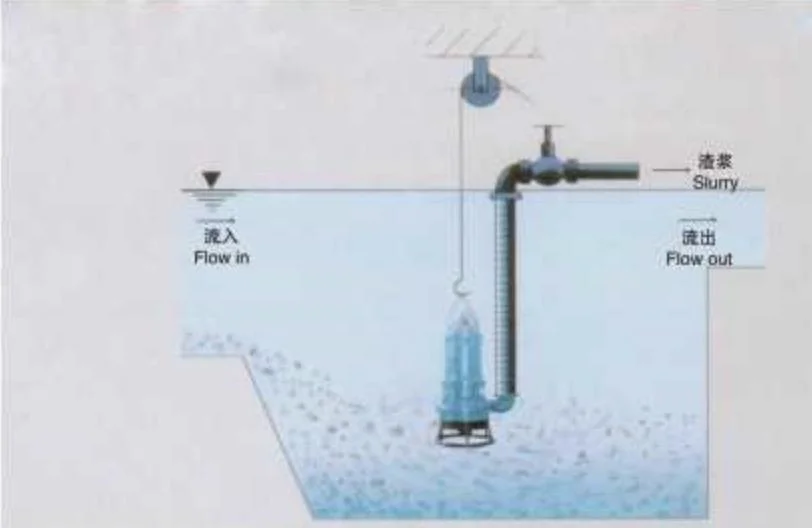

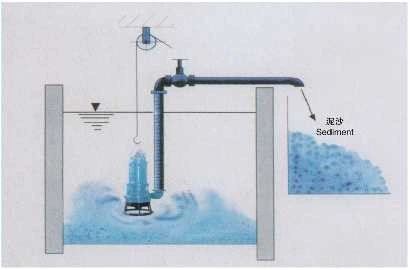

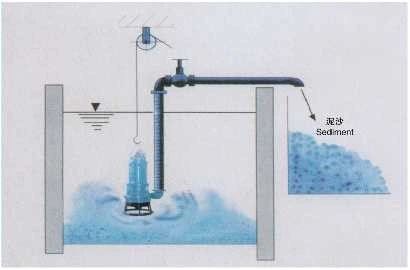

The series products are designed and manufactured by absorbing the foreign advanced technology. The wear-resistant material with high technology is adopted, so as to greatly improve the equipment life, and reduce the repair frequency. A set of mixing impeller is added at the bottom at the water pump except for the primary impeller, which can spray the sediment sludge to eddy flow, so that high concentration convey can be realized when the water pump has no auxiliary device. The unique sealing device can effectively balance the pressure inside and outside the oil chamber,so that pressure at both ends of mechanical seal is maintained balanced. It guarantees operation reliability of mechanical seal to the maximum limit, and greatly extends the service life. If necessary,overheat protection, inlet water detection and protection and other protection measures shall be adopted for the motor, which can be in long-term safe operation at harsh conditions. Meanwhile, the company can also add anti-condensation, bearing temperature measurement and other preventive measures can also be added according to users' requirements, so as to satisfy use in different occasions.

ZJQ submersible slurry pump is favored by the majority of users since entering the domestic market.

Compared with the common slurry pump, the series products have the foil wing features

it's not restricted by suction lift, the slag suction efficiency is high, and dredging is more thorough.

It is not required to equip the auxiliary vacuum pump, and the investment is more inexpensive.

It is not required to equip the auxiliary mixing device, and operation is simpler.

It is not required to build the complicated ground protection and fixing device when the motor is inserted under water, which is simple and convenient.

The mixing impeller directly contacts the deposition surface, and the depth is controlled through the submerged depth.Therefore, concentration control is more free.

The equipment is directly inserted into water for work,there is no noise or vibration, and the site is more tidy.

| Model | ZJQ |

| Outlet diameter (mm) | 65-400 |

| Flow(m³/h) | 25-2000 |

| Lift(m) | 15-80 |

| Motor power(KW) | 3-132 |

| Rotating speed(rpm) | 980/1460 |

| Max. granularity of interrupted passing(mm) | 14-60 |

| Weight(KG) | 125-4000 |

Type submersible dredging pump, wet ends and casing all in high chrome(A05) material.High abrasion resistance and corrosion resistance.

Type submersible dredging pump, wet ends and casing all in high chrome(A05) material.High abrasion resistance and corrosion resistance.

Pump could be install with agitators under customer requirement. Agitators could be increase the amount of solids absorption. The set could be 2 or 3.

Pump could be install with agitators under customer requirement. Agitators could be increase the amount of solids absorption. The set could be 2 or 3.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral export wooden case . If you have legally registered patent, we can pack the goods in

wooden case with your own marks after getting your authorization letters.

Q2. What is your termsof payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, etc.

Q4. How about your delivery time?

A: Generally, it will take from 10 dasys to 30 days after receiving your advance payment according to the pump's material. The

specific delivery time also depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test the pumps before delivery .

Q8: How do you make our business long-term and good relationship?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they are from.