Basic Info.

Model NO.

80TFJ-15K

Position of Pump Shaft

Horizontal Pump

Pump Casing Combined

Horizontal Split Pumps

Mounting Height

Suction Centrifugal

Impeller

Closed

Usage

Pump, Pumps, Circulating Pump

Transport Package

Standard Export Packing

Specification

as the model

Trademark

Gongyuan

Origin

China

HS Code

8413709990

Production Capacity

1000 Set/ Month

Product Description

Overview

TFJ series centrifugal pump with wear-resistant and corrosion-resistant is connected by the coupling. The flow parts of the pump (pump cover, pump body, impeller, cavity, auxiliary impeller, etc.) are all molded with high quality natural rubber. The rubber formula is researched and developed by us, and it is a forming after heating and moulding by various special processes such as rubber mixing and vulcanization, then it has excellent performance of wear resistance, corrosion resistance and temperature resistance. The pump with novel structure is convenient for maintenance. Application

At present, the TFJ type special wear-resistant, corrosion-resistant and temperature-resistant pump produced by our company is widely used in dyes, pigments, solar energy (silicon carbide powder for silicon wafer cutting enterprises, silicon carbide mortar recycling enterprises), chemical industry, sludge treatment, desulfurization and dust removal, electronics , sewage treatment, titanium dioxide, biological fermentation, mining and non-ferrous smelting (manganese, zinc, copper, molybdenum, nickel, etc.), chemical fiber textile and other industrial systems that have corrosive clear liquid or contain a large amount of particulate media. At present, it is the supporting products of major environmental protection companies, the Academy of Environmental Sciences, professional design institutes, silicon carbide slicing machine tool enterprises and so on.

Pump Sealing

The pump design adopts the K-type auxiliary impeller dynamic seal with a special structure, which is mainly composed of the auxiliary impeller dynamic seal and the K-type skeleton seal. Compared with conventional mechanical seals and packing seals, the sealing device has good sealing performance, no leakage, and is more durable. , No cooling water cooling sealing device is required when the pump is running (water cooling and sealing can be used for special positions), especially for supporting filter presses and transporting corrosive media containing particles. The sealing principle is as follows:

During operation, the centrifugal force generated by the rotation of the auxiliary impeller makes the sealed chamber in a negative pressure state, thereby preventing the liquid from leaking out. (The direction of the blades of the auxiliary impeller and the impeller are opposite);

When stopping, the auxiliary impeller stops rotating, the sealing ring part changes from negative pressure to positive pressure, and the lip of the rubber oil seal tightly wraps the shaft sleeve under pressure, thus playing a sealing role.

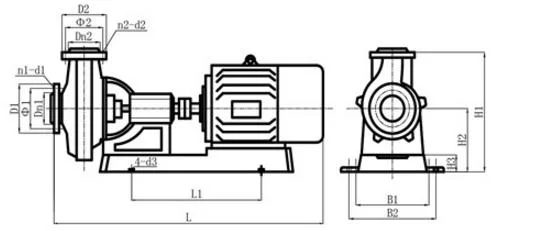

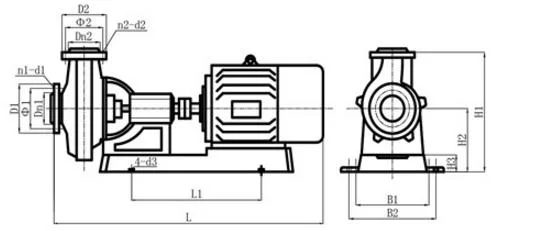

Outer Drawing

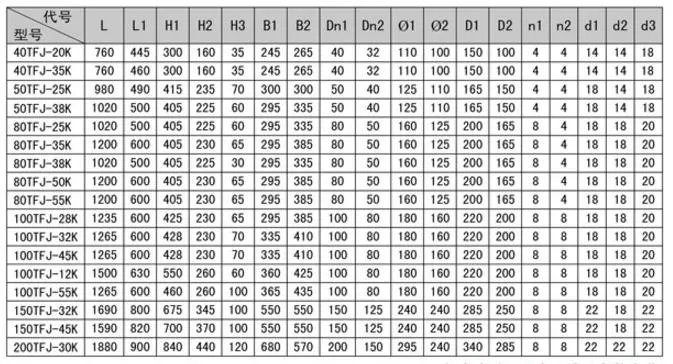

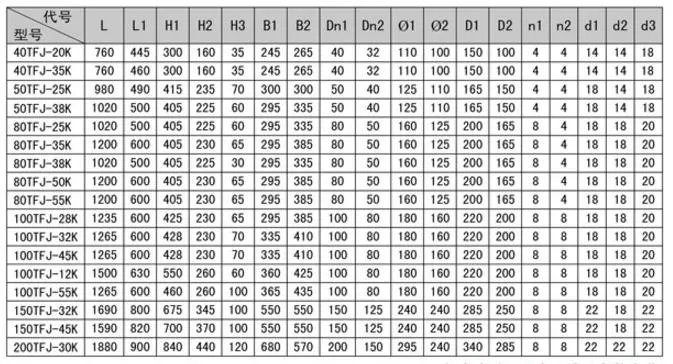

Technical data sheet

Technical data sheet

| No. | Model | Flow (m3/h) | Head H (m) | Rotating speed (r/min) | Motor power N (KW) | Inlet & outlet diam (mm) | Suction head (m) |

| 1 | 40TFJ-15A | 5 | 15 | 2900 | 1.5 | 40/32 | 6 |

| 2 | 40TFJ-20A | 8 | 20 | 2900 | 2.2 | 40/32 | 6 |

| 3 | 40TFJ-20B | 12 | 20 | 2900 | 3 | 40/32 | 6 |

| 4 | 40TFJ-30B | 20 | 30 | 2900 | 3 | 40/32 | 6 |

| 5 | 40TFJ-35K | 18 | 35 | 2900 | 3 | 40/32 | 6 |

| 6 | 50TFJ-15K | 15 | 15 | 1450 | 3 | 50/40 | 4 |

| 7 | 50TFJ-25K | 18 | 25 | 2900 | 4 | 50/40 | 6 |

| 8 | 50TFJ-38K | 20 | 38 | 2900 | 5.5 | 50/40 | 6 |

| 9 | 50TFJ-50K | 18 | 50 | 2900 | 5.5 | 50/40 | 6 |

| 10 | 50TFJ-65K | 30 | 65 | 2900 | 15 | 50/40 | 6 |

| 11 | 80TFJ-15K | 25 | 15 | 1450 | 4 | 80/50 | 4 |

| 12 | 80TFJ-25K | 35 | 25 | 2900 | 5.5 | 80/50 | 6 |

| 13 | 80TFJ-35K | 50 | 35 | 2900 | 11 | 80/50 | 6 |

| 14 | 80TFJ-38K | 35 | 38 | 2900 | 7.5 | 80/50 | 6 |

| 15 | 80TFJ-50K | 20 | 50 | 2900 | 7.5 | 80/50 | 6 |

| 16 | 80TFJ-45K | 60 | 45 | 2900 | 11 | 80/50 | 6 |

| 17 | 80TFJ-55K | 40 | 55 | 2900 | 11 | 80/50 | 6 |

| 18 | 80TFJ-20K | 80 | 20 | 960 | 15 | 80/80 | 2.5 |

| 19 | 80TFJ-40K | 100 | 40 | 1450 | 22 | 80/80 | 4 |

| 20 | 100TFJ-28K | 80 | 28 | 2900 | 11 | 100/80 | 6 |

| 21 | 100TFJ-32K | 100 | 32 | 2900 | 15 | 100/80 | 6 |

| 22 | 100TFJ-45K | 100 | 45 | 2900 | 18.5 | 100/80 | 6 |

| 23 | 100TFJ-55K | 90 | 55 | 2900 | 18.5 | 100/80 | 6 |

| 24 | 100TFJ-50K | 100 | 50 | 2900 | 22 | 100/80 | 6 |

| 25 | 100TFJ-12K | 40 | 12 | 1450 | 11 | 100/80 | 4 |

| 26 | 100TFJ-15k | 70 | 15 | 1450 | 15 | 100/80 | 4 |

| 27 | 100TFJ-40K | 150 | 40 | 1450 | 30 | 100/80 | 4 |

| 28 | 100TFJ-55K | 130 | 55 | 1450 | 30 | 100/80 | 4 |

| 29 | 100TFJ-20K | 120 | 20 | 960 | 15 | 100/80 | 2.5 |

| 30 | 150TFJ-20K | 200 | 20 | 1450 | 18.5 | 150/125 | 4 |

| 31 | 150TFJ-32K | 200 | 32 | 1450 | 30 | 150/125 | 4 |

| 32 | 150TFJ-45K | 200 | 45 | 1450 | 37 | 150/125 | 4 |

| 33 | 150TFJ-50K | 220 | 50 | 1450 | 55 | 150/125 | 4 |

| 34 | 150TFJ-20K | 400 | 20 | 1450 | 55 | 150/125 | 4 |

| 35 | 200TFJ-30K | 400 | 30 | 1450 | 75 | 200/150 | 4 |

| 36 | 200TFJ-40K | 500 | 40 | 1450 | 110 | 250/200 | 4 |

| 37 | 250TFJ-50K | 600 | 30 | 1450 | 132 | 250/200 | 4 |

| 38 | 300TFJ-32K | 800 | 32 | 1450 | 132 | 300/250 | 4 |

| 39 | 300TFJ-30K | 1000 | 30 | 1450 | 160 | 300/250 | 4 |

| 40 | 300TFJ-30K | 1200 | 30 | 1450 | 200 | 300/250 | 4 |