- Overview

- Product Description

- Product Parameters

- Company Profile

- Our Advantages

- Certifications

- FAQ

Basic Info.

Product Description

The automatic chemical dosing system realizes the metering and adding of medicines to the system through the mechanical pulse action and stroke adjustment principle of the metering pump. It realizes automatic dosing through the following two control modes. Time control mode: use the microcomputer time control switch to control the timing opening and closing of the metering pump and the sewage valve, so as to realize timing dosing and timing sewage discharge. Indication control mode: The change of water quality index controls the real-time opening and closing of metering pump and sewage valve, realizing automatic dosing and automatic sewage discharge.

Key Elements

1.PLC control

2.Metering pump

3.Dosing tank / Chemical tank

4.On-line monitoring for corrosion rate(Optional)

5.On-line monitoring for PH(Optional)

6.On-line monitoring for turbidity(Optional)

7.On-line monitoring for ORP(Optional)

8.Fouling thermal resistance meter, mixer, PLC, GPRS(Optional)

| Name | Type | Dimensions(mm) | Import /Outlet Diameter |

| Single Pump Single Barrel (Time Control) | YTZDJ-2000D | 640*670*1650 | DN25 |

| Single Pump Single Barrel (With Conductivity and PH Detector) | YTZDJ-2000DP | 640*670*1900 | DN25 |

| Double Pumps Double Barrels (Time Control) | YTZDJ-2000S | 670*1260*1650 | DN25 |

| Double Pumps Double Barrels (With Conductivity and PH Detector) | YTZDJ-2000SP | 670*1260*1900 | DN25 |

| Can be configured on request. Corrosion rate online monitor, turbidity online monitor, ORP online monitor, fouling thermal resistance meter, etc. Mixer, PLC, GPRS, etc. can be configured as required. | |||

Features

1.Various proportions of water treatment chemicals can be added arbitrarily, and the measurement data is accurate.

2.High degree of automation, simple operation and low energy consumption.

3.Installation, use and maintenance are simple and convenient.

4.Strong corrosion resistance, strong acid and alkali resistance, safe and reliable.

5.If the user needs, the system can be remotely controlled and integrated into the computer management system

Functions and Benefits

To provide effective protection from freshwater/seawater corrosion;

To prevent the incrustation of the condenser and the heat exchanger;

To inhibit the formation of organisms and the attachment of biological membrane;

To gradually remove the blockage caused by organic and inorganic corrosion within the system;

Supplementary water does not need a chemical pre-treatment;

Applicable to freshwater, seawater and recycled wastewater and a higher concentration factor is allowable;

Applicable to steel, iron, alloy, plastic, cement, timber and other materials;

Compatible with a variety of water treatment chemicals;

Saving power and water and no wastewater retreatment burden;

Be environmental friendly and quickly and completely biodegradable.

Applications

• Industrial, Air Conditioning Circulating Water and Boiler Water

* To inject corrosion and scale inhibitors, complexing agents for cyanide-free electroplating.

• Textile Printing and Dyeing Industry

* To add chelating agents and oxygen bleach stabilizers.

• Water Treatment System

* To add chemicals to tapping water, waste water and sewage system.

Cooling Water System

I. Common Problems of Cooling Water System

1.Corrosion

Cooling water systems are an ideal environment for the reversion of the metal to the original oxide state. This reversion process is called corrosion.

2.Scale

Minerals such as calcium carbonate, calcium phosphate, and magnesium silicate are relatively insoluble in water and can precipitate out of the water to form scale deposits when exposed to conditions commonly found in cooling water systems.

3.Fouling

The deposition of suspended material in heat exchange equipment is called fouling. Foulants can come from external sources such as dust around a cooling tower or internal sources such as by-products of corrosion.

4.Biological Contamination

Cooling water systems provide an ideal environment for microbial organisms to grow, multiply, and cause deposit problems.

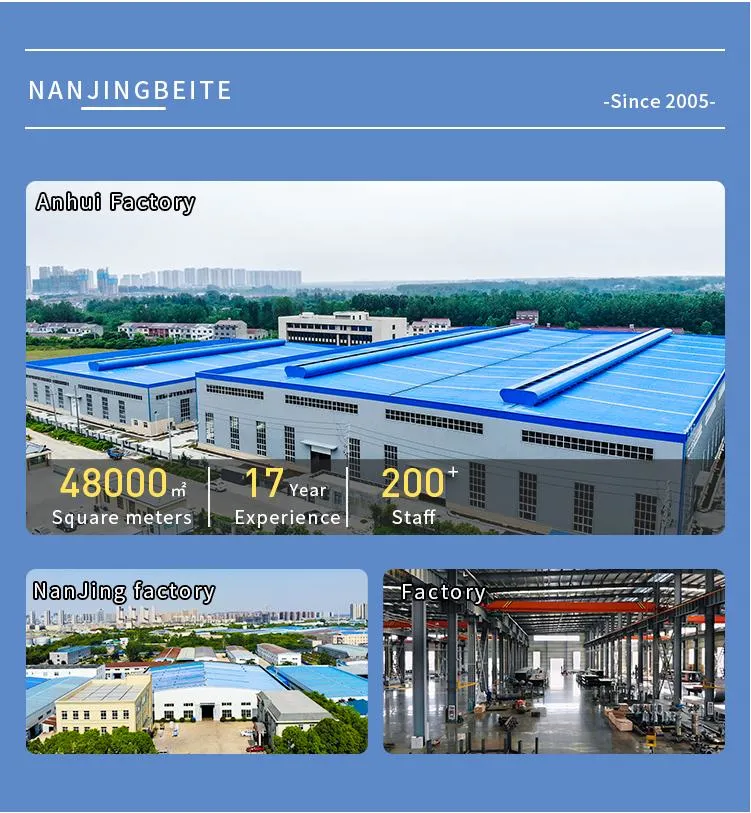

The tradition of Nanjing Beite AC Equipment Co., Ltd began in 2005. It is a compre hensive enterprise integrating R&D, design, production and sales. Leading the field of HVAC circulating water equipment for over 17 years, through our strategic partnerships, extensive manufacturing and design experience, advanced R&D capabilities, highly skilled engineers and advanced technology, we provide world-class solutions to our renowned customers in the region. Utilizing advanced mechanical equipment and cutting-edge technical facilities, it has become one of the world's leading suppliers of filters, constant pressure water supply equipment, volumetric heat exchangers, and dosing equipment. Nanjing Beite is a high-tech comprehensive enterprise specializing in the research and development, production, sales and after -sales service of HVAC water treatmente quipment.

Professional Production Line

Our Team

Exihibtion

Q1: Can I have a sample?

A : Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q2: What is your lead time for production?

A : Generally Sample needs 1-3 days,mass production needs 15-30 days,also depands on your request.

Q3 : Can you accept mixed batch of different products?

A : Yes,we can provide different product mix wholesale.

Q4: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q5 : What is the warranty for your products?

A :We provide one year warranty for the products..

Q6 : Are you trading company or manufacturer?

A :Yes,We are manufacturer.Welcome to visit our factory and check our pruducts.

Q7: What terms of payment do you accept?

A: Payment method:T/T,Paypal,western union.

Q8: What is your delivery time?

A: Delivery term:15-30 working days.