Basic Info.

Position of Pump Shaft

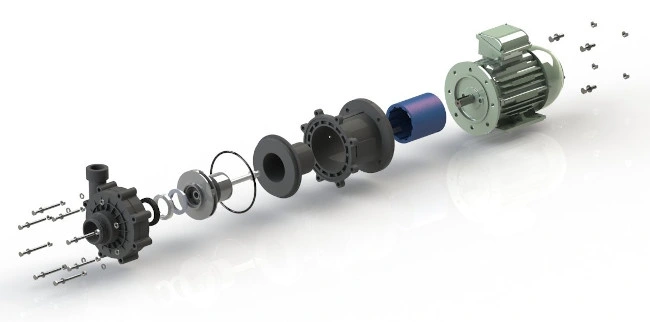

Horizontal Pump

Pump Casing Combined

Horizontal Split Pumps

Mounting Height

Since Irrigation Centrifugal Pumps

Impeller

Closed

Usage

for High Specific Gravity Solutions

Transport Package

Carton and Pallet

Trademark

DJ pump

Origin

China

HS Code

8413709940

Production Capacity

50000 Units/Year

Product Description

Materials Used in Centrifugal Pumps

Cast iron, cast steel, stainless steel, bronze, brass, carbon structural steel composite materials, alloy steel, and non-metallic materials are some of the materials used to make centrifugal pumps.

- Cast iron - This is the most common material used to make centrifugal pumps. It provides high tensile strength and abrasion resistance correlated to high-pressure ratings. It is also durable.

- Stainless steel - Austenitic stainless steel is the most common stainless steel that is used to make pumps. Stainless steel is usually used for chemical pumps as it is corrosion resistant. Its tensile strength is remarkably high.

- Cast steel - This material is suitable for high-pressure working conditions and has good mechanical properties. Though its corrosion resistance is not as good compared to other types of stainless steel used in corrosive and other chemical applications.

- Carbon structural steel - This material is widely used as pump shaft material where no corrosion is required.

- Alloy steel - It is usually used as a material in pump shafts for high-strength.

- Non-metallic materials - This material in pumps is mainly used for sealing purposes for example polytetrafluoroethylene, rubber, nitrile rubber, and fluorine. Polytetrafluoroethylene has excellent high temperature resistance and corrosion resistance. Is used for static seals of mechanical seals and chemical pump gaskets. It is advisable to use almost all chemical media within 250°C.

- Bronze - Can be used for the body of the pump. It helps the sealing of the pump body. For larger centrifugal pumps, tin bronze is used as a material for the body. Although nickel aluminum bronze is corrosion resistant and has the best mechanical properties it is expensive and incompetent.

- Composite materials - to improve the chemical resistance of the pump, a lining can be installed in the volute. The materials used for the lining can be rubber. Graphite monolithic ceramic and pumps are used in particular corrosive liquids,which is used in the pulp and paper industry and metal finishing industry. Composite materials are also used to make pump bodies.

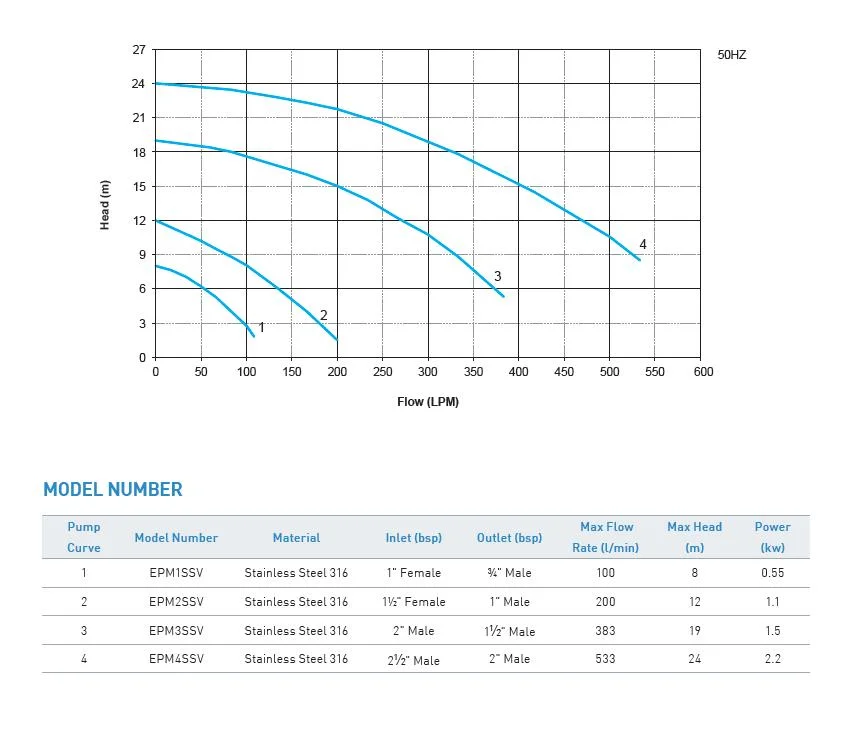

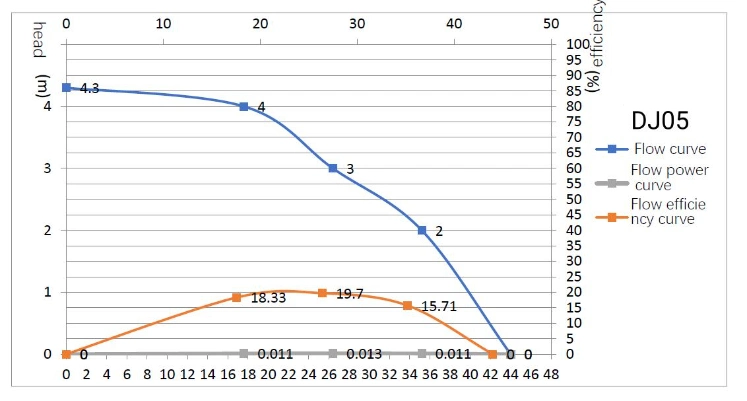

| TYPE | Inlet Size | Outlet Size | Max flow(LPM) | Max head(M) | Power(kw) | ||

| PP | PVDF | PPS | |||||

| DJ0.5PPE | DJ0.5KV | DJ0.5PPS | 3/4" | 3/4" | 50 | 5 | 0.065 |

| DJ1PPE | DJ1KV | DJ1PPS | 1'' | 1'' | 90 | 7 | 0.15 |

| DJ2PPE | DJ2KV | DJ2PPS | 1'' | 1'' | 120 | 9 | 0.37 |

| DJ2HPPE | DJ2HKV | DJ2HPPS | 1" | 1" | 160 | 15 | 0.55 |

| DJ3PPE | DJ3KV | DJ3PPS | 1-1/2" | 1-1/2" | 240 | 15 | 0.75 |

| DJ3HPPE | DJ3HKV | DJ3HPPS | 1-1/2" | 1-1/2" | 300 | 17 | 0.75 |

| DJ4PPE | DJ4KV | DJ4PPS | 1-1/2" | 1-1/2" | 350 | 17 | 1.1 |

| DJ5PPE | DJ5KV | DJ5PPS | 2" | 1-1/2" | 400 | 23 | 1.5 |

| DJ6PPE | DJ6KV | DJ6PPS | 2" | 1-1/2" | 500 | 26 | 2.2 |

| DJ7PPE | DJ7KV | DJ7PPS | 2- 1/2" | 2" | 800 | 31 | 3.75 |

| DJ8PPE | DJ8KV | DJ8PPS | 2- 1/2" | 2" | 980 | 35 | 5.5 |

| DJ9PPE | DJ9KV | DJ9PPS | 2- 1/2" | 2" | 1000 | 38 | 7.5 |